Add to Cart

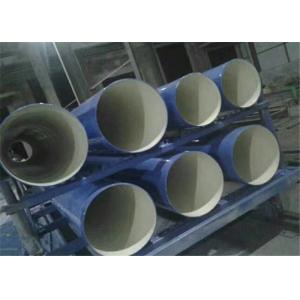

Alkali Resistance Plastic Coated Steel Pipe Epoxy Resin Powder Coated

Mine pipe refers to a product specially developed for special underground environmental conditions, which has the advantages of flame retardant, antistatic, corrosion resistance, long service life and strong safety. It is mainly used in five systems: mine drainage pipe (KS), mine grouting pipe (KJ), mine positive pressure air pipe (KFZ), mine negative pressure air pipe (KFF), mine gas drainage pipe (KW).

size:HOSP-TEP(PE)-KW(-0.097)/101.6~1118

size:DN100mm~DN1000mm

Pressure Grade

Pipeline for gas drainage in underground coal mine, bearing pressure - 0.097 - 1.0 MPa.

Performance characteristics

1) Light weight of pipe: the base pipe is spirally welded corrugated steel pipe, which is thinner than other pipes of the same specification and type. It greatly reduces the weight of pipe and is convenient for transportation and installation in underground coal mine. It reduces the labor intensity and improves the construction efficiency.

2) High stiffness of pipe ring: high negative pressure performance, ring stiffness to meet SN16.

3) Chemical corrosion resistance, weathering resistance and aging resistance are very high: the coating can prevent metal oxidation, and has the corrosion resistance of acid, alkali and salt. The product has excellent anti-aging performance, and its service life is much higher than other pipes. The product can be painted with flange to ensure the anticorrosion effect of the whole pipeline.

National Standard Specification and Coating Thickness

| DN | internal coating | external coating | ||||

| Ordinary level | Reinforcement level | polyethylene | epoxy resin | |||

| Ordinary level | Reinforcement level | Ordinary level | Reinforcement level | |||

| 15 | >0.4 | >0.3 | >0.5 | >0.6 | >0.3 | >0.35 |

| 20 | ||||||

| 25 | ||||||

| 32 | ||||||

| 40 | ||||||

| 50 | ||||||

| 65 | ||||||

| 80 | >0.5 | >0.35 | >0.6 | >1.0 | >0.35 | >0.4 |

| 100 | ||||||

| 125 | ||||||

| 150 | ||||||

| 200 | >0.6 | >0.8 | >1.2 | |||

| 250 | ||||||

| 300 | ||||||

| 350 | >1.3 | |||||

| 400 | ||||||

| 450 | ||||||

| 500 | ||||||

| 550 | >0.8 | >0.4 | >1.0 | >1.5 | >0.4 | >0.45 |

| 600 | ||||||

| 650 | ||||||

| 700 | ||||||

| 750 | ||||||

| 800 | >1.0 | >0.45 | >1.2 | >1.8 | >0.45 | >0.5 |

| 850 | ||||||

| 900 | ||||||

| 1100 | ||||||

| 1200 | ||||||

| 1400 | ||||||

| 1600 | ||||||

| Remarks | Seamless steel pipe, spiral welded pipe and straight welded pipe can be selected as the base pipe, and the thickness of plastic coating can be processed according to customer's requirements. | |||||